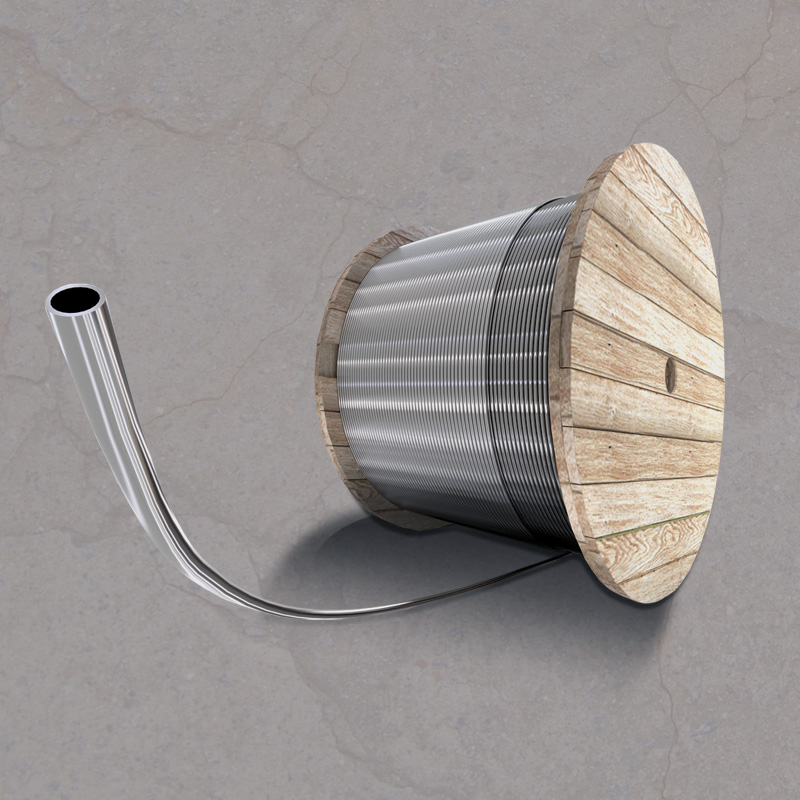

Smart Completions provides either welded or seamless hydraulic control line, supplied by leading manufacturers, for subsurface applications. Hydraulic control line is available in three materials, varying wall thicknesses, and a wide range of working pressure ratings. The line is supplied on spools to exact length requirements. Upon request, it is pressure tested hydraulically, purged with clean oil, and sealed on both ends prior to shipping.

Welded hydraulic control line is sunk-drawn to ASTM specification A269 and is available in any length. Seamless hydraulic control line is available in lengths to 500 ft [152 m]. Lengths greater than 500 ft [152 m] are joined by orbital welding, which also meets ASTM specification A-269

Material types for hydraulic control line include T316/T316L stainless steel, Incoloy 825, and Incoloy 625. Control line made of T316/T316L stainless steel is suitable for sweet to moderately corrosive environments. Incoloy 825 and 625 are suitable for severely corrosive environments and high working pressures and temperatures. Control system fluids must be compatible with the environments and operating temperatures of the control line.

Control line encapsulation also is available, where requested, to pro vide additional crush and abrasion resistance during installation. The encapsulation material should be matched for compatibility with well fluids and temperature requirements.

Hydraulic fittings

Smart Completions provides its proprietary inverted dual ferrule connections as a standard across the entire safety valve range, except for special order or ultrahigh pressure applications. The 1⁄4in fittings feature silver coated threads to prevent galling. The nut is avail able in either Inconel® 925 or Inconel 718. The ferrules are available in 316 stainless steel or Incoloy 825 but should be matched to the control line material to ensure that the ferrule will bite into the control line and is suitable for the application. These fittings are rated to the working pressure of the control line. Pressure tests of these fittings to 40,000 psi have been achieved, using suitable control line, with no failures

Banding kits

Banding kits, assembled from components supplied by leading manufacturers, contain the items and tools necessary to rigidly band hydraulic control line to the tubing string. Banding protects the line and helps support control line and tubing string weight to reduce tensile loading on the wellhead fitting of the line. Supplied in either 1⁄2 or 5⁄8in widths, these banding kits are available in 316 stainless steel for sweet to moderately corrosive environments or 400 Monel for more corrosive environments. In completions using multiple conduits, Smart Completion recommends the use of cast clamp systems.

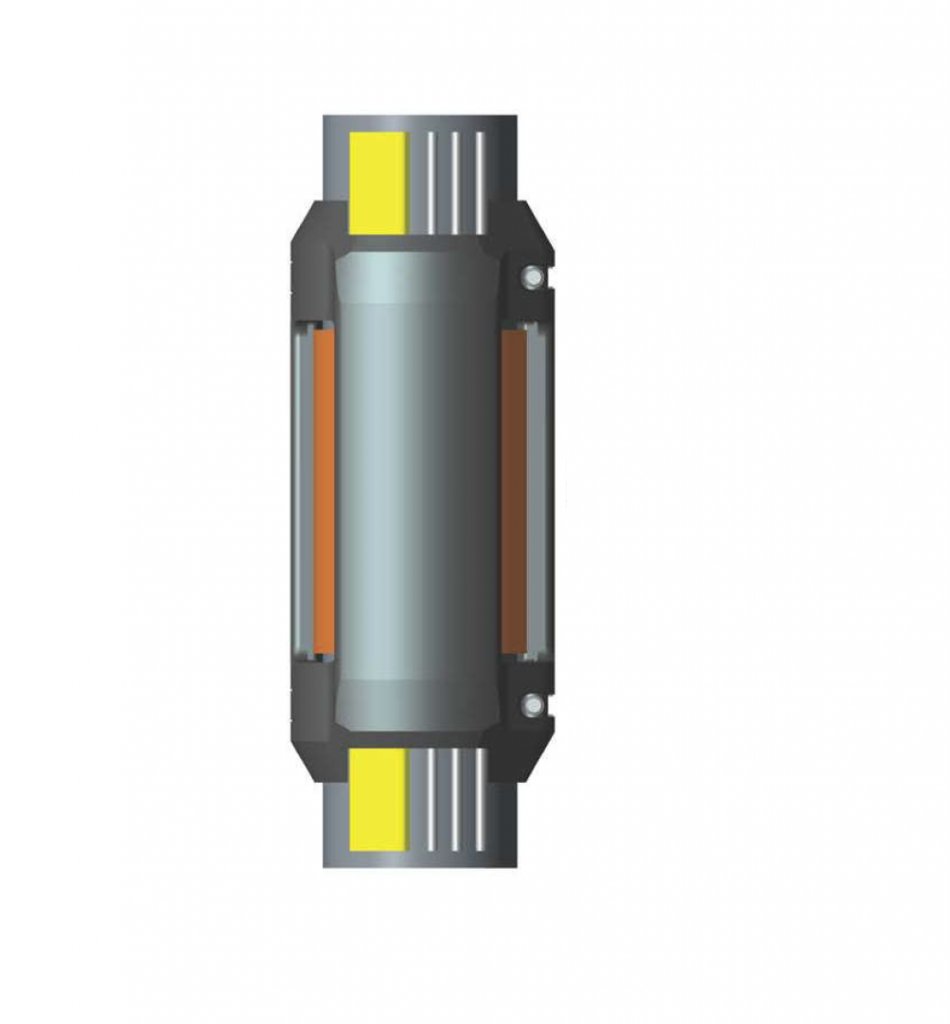

Cross Coupling Protectors

Cross Coupling Protectors can be provided for tubing from 2-3/8 in to 9-5/8 in, for all coupling types and for all control line and cable specifications Cross Coupling Protectors are available in a variety of materials and configurations to protect cables and capillary tubing traveling down-hole. Customized variations allow for any cable/cap string configuration needed. Low Carbon Steel, various Stainless Steel, Inconel, Monel and other materials options available to match the requirements of your well composition.