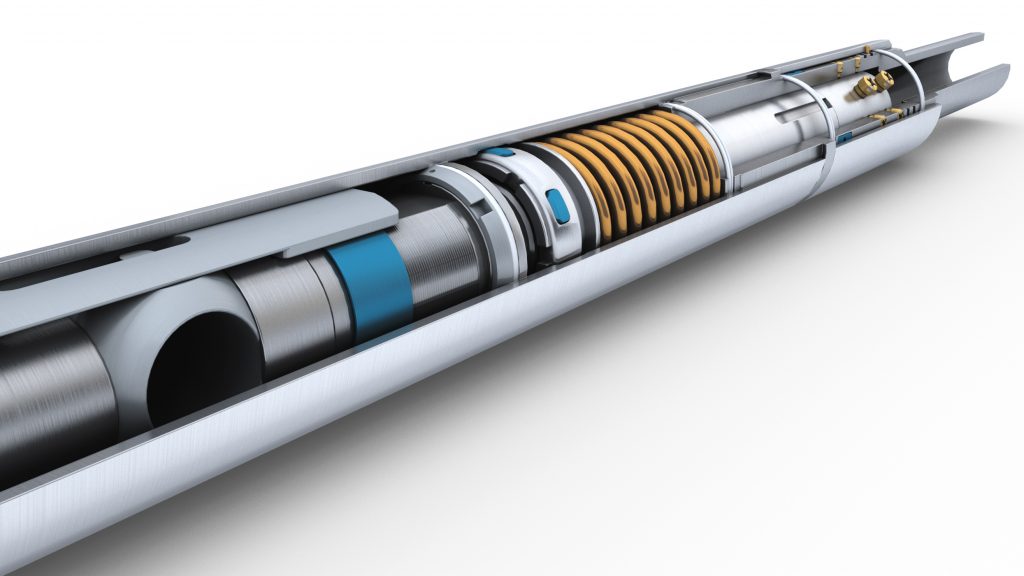

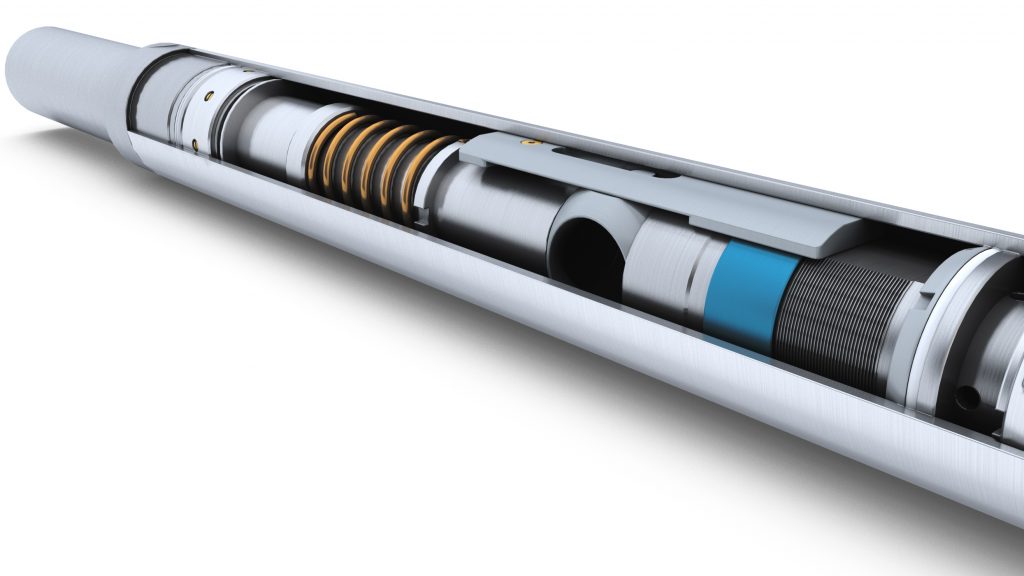

Prevent formation damage and minimize workover costs with isolation valves that safeguard reservoirs by providing a reliable barrier within the completion string. Simultaneously minimize risks by isolating the formation and containing reservoir fluids, which increases efficiency by enabling batch drilling and completion operations.

By isolating the formation, the valve can contain reservoir fluids, provide a barrier, enhance production, simplify completion operations, and provide increased well bore safety.

The valve provides a two-way barrier during pump replacement and re-completion operations. FIV valves are particularly valuable in protecting high permeable reservoirs from completion fluid damage.

Benefits

- Allows multiple pump replacements without killing the well

- Isolates formations without applying kill fluid to the formation

- Eliminates fluid losses during completion installations

- Improves well productivity by preventing formation damage

- Reduces costs associated with well interventions

- Shortens rig time during completion

- Acts as barrier valve to control well

Features

- Provides reliability through design based on proven DST technology

- Unlimited mechanical opening and closings using shifting tool

- Suitable for high-pressure high-temperature, (HPHT) environments

- Bidirectional sealing holds pressure from above and below the valve

- Debris tolerant ball valve operates with debris sub

- Reliable, field-proven design

- Fit-for-purpose engineering